Welcome To MZ STEEL

Wholesale Discount 1.4304 Stainless Steel Sheets/Coils - hot rolled stainless steel coil & sheet – Mizhang

Wholesale Discount 1.4304 Stainless Steel Sheets/Coils - hot rolled stainless steel coil & sheet – Mizhang Detail:

Product Detail:

ASTM CR Stainless Steel Coils With 0.25mm-1.0mm for Construction.

Quick Detail:

| Grade: | 200s,300s | Standard: | JIS,AISI,ASTM | Length: | The length of the factory |

| Thickness: | 0.25mm-1.0 mm or as request | Width: | 1000mm-2000mm | Place of Origin: | Shanxi China (Mainland) |

Description:

1. Name: 201 304 stainless steel coil

2. Finish: 2B, 2D, No.4, BA, 8K, HL and so on

3. Thickness: 0.25mm to 1.0mm

4. Width:max 1500mm

5. Length: as customers’ requested

6. Payment: TT 30% for deposit, Balance against the copy of B/L; or L/C at sight

7. Shipment: 15 to 20 days after the receive of the deposit

8. Ship term: FOB SHANGHAI,NINGBO port or CNF import port

9. Minimum quantity: 10 tons

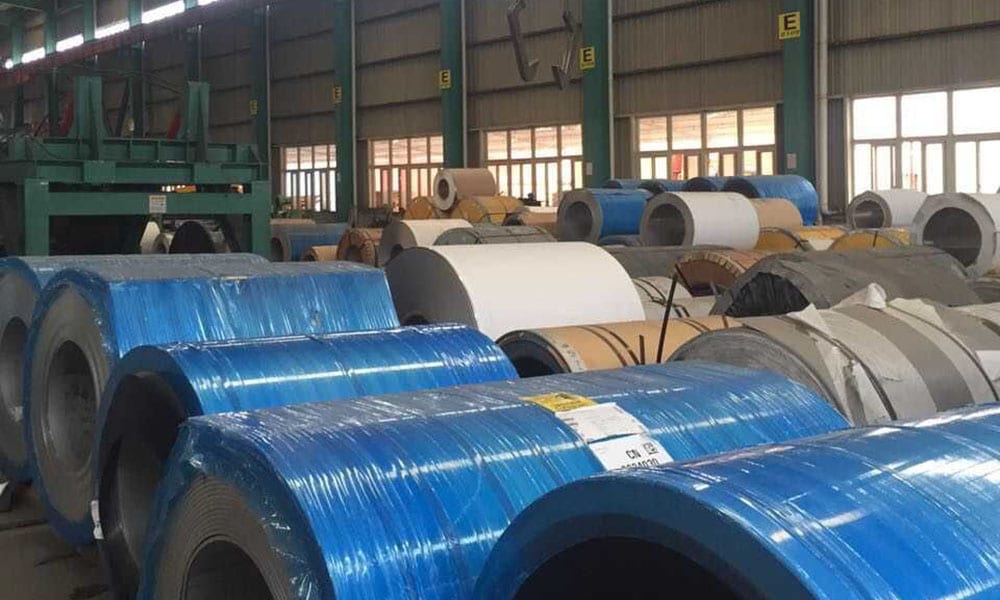

We are stainless steel factory located in Wuxi city, Jiangsu province.welcome come to visit our factory.

Specifications:

| Product name | Stainless Steel Coil |

| Standard | ASTM, AISI, JIS, GB, DIN |

| Place of Origin | Shanxi, Guangzhou, Zhang Jia Gang, Shanghai of China (Mainland) |

| Brand Name | TISCO , LISCO, ZPSS, Bao Steel, Krupp |

| Type | Coil |

| Certification | ISO Certificate, Mill Test Certificate |

| Application | Kitchenware, Tanks, Food Processing, cutlery, construction, household hardware, surgical instruments, major appliances, industrial equipment and as an automotive and aerospace structural alloy |

| Technical treatment | Cold Rolled, Hot Rolled |

| MOQ | 1 Metric Ton |

| Terms of delivery | FOB, CNF, CIF |

| Terms of Payment | L/C, T/T |

| Port of Loading | Tianjin / Shanghai / Guangzhou of China |

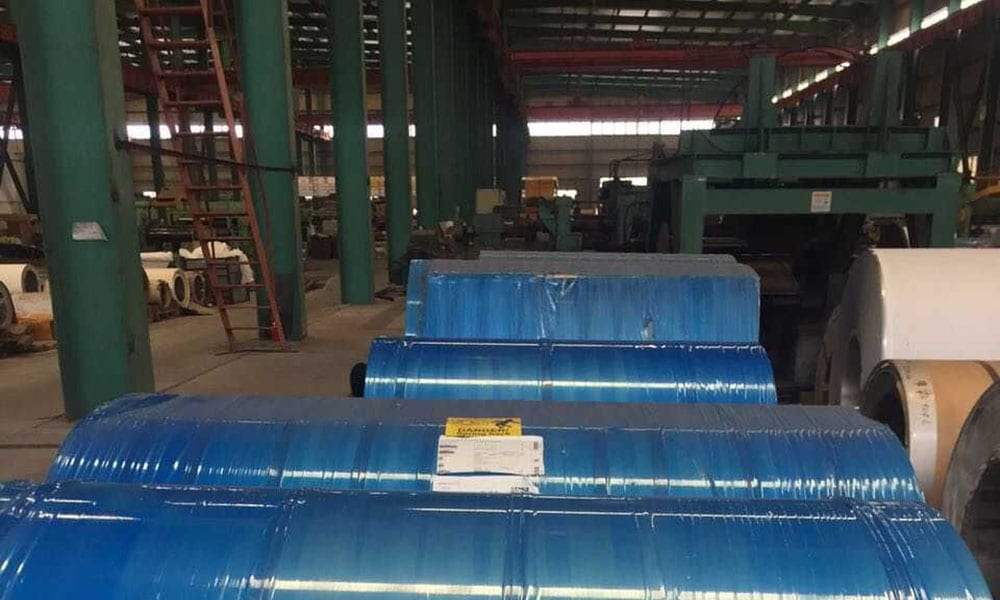

| Packing | In bundles, packed with Water proof paper and wooden pallet. To be packed strongly avoid damage during transportation, and can be also according to the regulations and customer’s requests. Furthermore,products packages also are tagged clear on the outside for easy identification of the product and quality information. |

| Time of delivery | Normally delivery within 15 days from stocks. |

| Stock | Ready In stocks |

Chemical composition

| Grade | C | Si | Mn | P | S | Ni | Cr | Mo |

| 201 | ≤0.15 | ≤1.00 | 5.5-7.5 | ≤0.060 | ≤0.03 | 3.5-5.5 | 16.0-18.0 | |

| 202 | ≤0.15 | ≤1.00 | 7.5-10.00 | ≤0.060 | ≤0.03 | 4.0-6.0 | 17.0-19.0 | |

| 301 | ≤0.15 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 6.0-8.0 | 16.0-18.0 | |

| 302 | ≤0.15 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 8.0-10.0 | 17.0-19.0 | |

| 304 | ≤0.07 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 8.0-10.0 | 18.0-20.0 | |

| 304L | ≤0.030 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 9.0-13.0 | 18.0-20.0 | |

| 310S | ≤0.08 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 19.0-22.0 | 24.0-26.0 | |

| 316 | ≤0.08 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 10.0-14.0 | 16.0-18.0 | 2.0-3.0 |

| 316L | ≤0.03 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 12.0-15.0 | 16.0-18.0 | 2.0-3.0 |

| 321 | ≤0.08 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 9.0-13.0 | 17.0-19.0 | |

| 430 | ≤0.12 | ≤0.75 | ≤1.00 | ≤0.040 | ≤0.03 | ≤0.60 | 16.0-18.0 | |

| 430A | ≤0.06 | ≤0.50 | ≤0.50 | ≤0.030 | ≤0.50 | ≤0.25 | 14.0-17.0 |

Finish Introduction

| Surface Finish | Definition | Application |

| 2B | Those finished, after cold rolling, by heat treatment, pickling or other equivalent treatment and lastly by cold rolling to given appropriate luster. | Medical equipment, Food industry, Construction material, Kitchen utensils. |

| BA | Those processed with bright heat treatment after cold rolling. | Kitchen utensils, Electric equipment, Building construction. |

| NO.3 | Those finished by polishing with No.100 to No.120 abrasives specified in JIS R6001. | Kitchen utensils, Building construction. |

| NO.4 | Those finished by polishing with No.150 to No.180 abrasives specified in JIS R6001. | Kitchen utensils, Building construction, Medical equipment. |

| HL | Those finished polishing so as to give continuous polishing streaks by using abrasive of suitable grain size. | Building Construction. |

| NO.1 | The surface finished by heat treatment and pickling or processes corresponding there to after hot rolling. | Chemical tank, pipe |

Applications:

Stainless Steel Cold Coil applies to construction field ,ships building industry ,petroleum and chemical industries ,war and electricity industries ,food processing and medical industry, boiler heat exchanger ,machinery and hardware fields.

Competitive Advantage:

colorful, showing the splendor of your quality, wear-resistant as well, strong corrosion resistance and decorative effect, durable and beautiful in good taste.

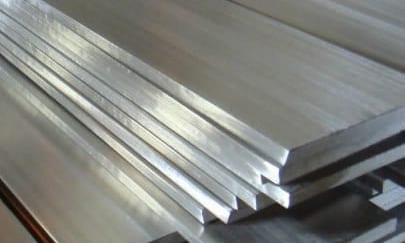

Product detail pictures:

Related Product Guide:

New Edgebanding Technology Gives A Competitive Edge | 8mm Precision Steel Rod

No protest against Chinese workers in Morowali nickel mining site, say police – National | 0.8mm Stainless Steel Sheet

We have state-of-the-art tools. Our products are exported towards the USA, the UK and so on, enjoying a fantastic reputation amongst customers for Wholesale Discount 1.4304 Stainless Steel Sheets/Coils - hot rolled stainless steel coil & sheet – Mizhang , The product will supply to all over the world, such as: Cape Town, Porto, Iraq, Our company always concentrate on the development of the international market. We have a lot of customers in Russia , European countries, the USA, the Middle East countries and Africa countries. We always follow that quality is foundation while service is guarantee to meet all customers.

In general, we are satisfied with all aspects, cheap, high-quality, fast delivery and good procuct style, we will have follow-up cooperation!

Products categories

WHY CHOOSE US

Since its establishment, our factory has been developing first world class products with adhering the principle

of quality first. Our products have gained excellent reputation in the industry and valuabletrusty among new and old customers..