Welcome To MZ STEEL

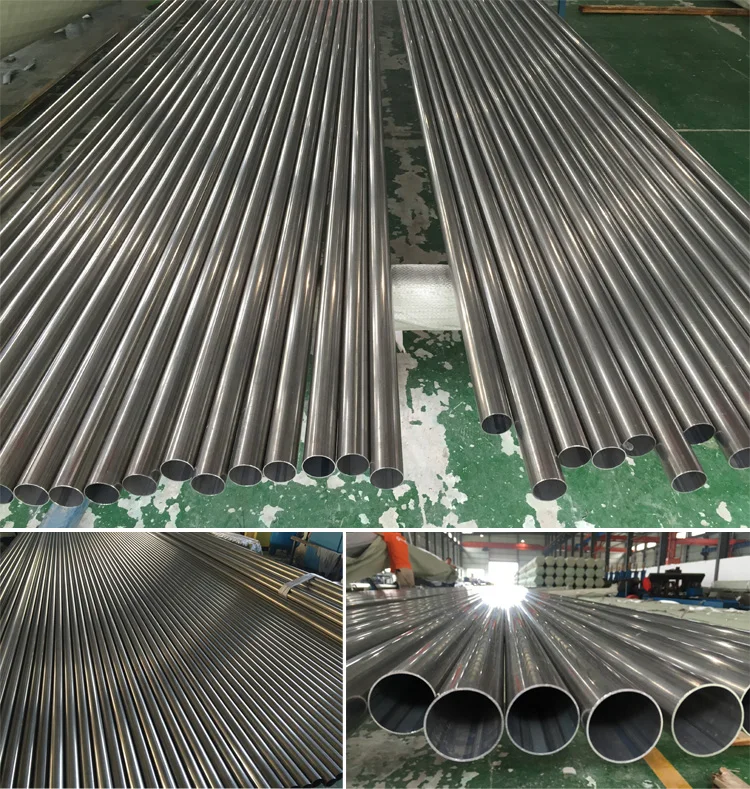

welding stainless steel boiler tube rolling piping for heat exchanger

Standard:ASTM, AiSi, DIN, EN, GB, JIS Place of Origin:ShangHai, China Brand Name:MZ Steel Number:ASTM A249/269/778/789, EN 10217-7 Type:Welded, piping stainless Steel Grade:300 Series

Application:shell and tube heat exchanger Certification:PED 2014/68/EU,AD 2000Merkblatt W0,ISO

Welding Line Type:Efw Tolerance:±10% Processing Service:Bending Grade:SS304,SS304L,SS316,SS316L

Inner and outer finish:bright annealing or pickling Thickness Tolerance:+/- 10% Material Grade:304 304L 316 316L

Length:up to 18.3 meter. Bright annealed: 1040℃ Welded seam treatment:inner welded seam removed

Product:welding stainless steel boiler tube rolling piping for heat exchanger Name:boiler tube rolling

Application machine:heat exchanger, boiler, condenser,evaporator

| HG 20537.2 | ASTM A249 (A1016) | GB / T 24593 | ||||||

| Outside Diameter (mm) | Ⅰ | Ⅱ | < 25.4 | ± 0.10 | ≤ 25 | ± 0.10 | ||

| <25 | ± 0.10 | >10~30 | ± 0.20 | ≥25.4~<38.1 | ± 0.15 | >25~40 | ± 0.15 | |

| ≥25~38 | ± 0.15 | >30~50 | ± 0.30 | ≥38.1~<50.8 | ± 0.20 | >40~50 | ± 0.20 | |

| >35~51 | ± 0.20 | >50 | ± 0.8% | ≥50.8~<63.5 | ± 0.25 | >50~65 | ± 0.25 | |

| >51~63 | ± 0.25 | >63.5~<76.2 | ± 0.31 | >65~75 | ± 0.30 | |||

| >63~76 | ± 0.30 | >75~100 | ± 0.38 | |||||

| Thickness (mm) | ± 10%S | ± 10%S | ± 10%S | |||||

| Length (mm) | +5 -0 |

D<50.8 | +3 -0 |

+5 -0 |

||||

| D ≥ 50.8 | +5 -0 |

|||||||

| Stainless Steel Mechanical Properties | ||||||||

| Grade | Tensile Strength | Yide Strength | Elogation | Hardness | Soluction Annealing | |||

| kgf/mm²(N/mm²) | kgf/mm²(N/mm²) | % | HRB(HV) | ℃ | ||||

| ASTM | TP 304 | ≥53 (515) | ≥21 (205) | ≥35 | ≤90 (200) | 1040℃-1150℃ Water Quenching |

||

| TP 304L | ≥50 (485) | ≥17 (170) | ||||||

| TP 316 | ≥53 (515) | ≥21 (205) | ||||||

| TP 316l | ≥50 (485) | ≥17 (170) | ||||||

| JIS | SUS 304 | ≥53 (520) | ≥21 (205) | 1010℃-1150℃ Water Quenching |

||||

| SUS 304L | ≥49 (480) | ≥18 (175) | ||||||

| SUS 316 | ≥53 (520) | ≥21 (205) | ||||||

| SUS 316L | ≥49 (480) | ≥18 (175) | ||||||

| GB | 06Cr19Ni10 | ≥53 (520) | ≥21 (205) | 1010℃-1150℃ Water Quenching |

||||

| 022Cr19Ni10 | ≥49 (480) | ≥18 (180) | ||||||

| 06Cr17Ni12Mo2 | ≥53 (520) | ≥21 (205) | ||||||

| 022Cr17Ni12Mo2 | ≥49 (480) | ≥18 (180) | ||||||

| EN | 1.4301 | (500-700) | ≥20 (195) | ≥40 | 1000℃-1100℃ Water Quenching |

|||

| 1.4307 | (470-670) | ≥18 (180) | ||||||

| 1.4401 | (510-710) | ≥21 (205) | 1020℃-1120℃ Water Quenching |

|||||

| 1.4404 | (490-690) | ≥19 (195) | ||||||

| A789 / A789M Permissible Variations in Dimensions | ||||||||

| Group | Size, Outside Diameter, in. [mm] | Permissible Variations in Outside Diameter, in. [mm] | Average Wall Permissible Variations in Wall Thickness, % | Minimum Wall Permissible Variations in Wall Thickness, % | Permissible Variations in Cut Length,in. [mm] | Thin Walled Tubes | ||

| Over | Under | Over | Under | |||||

| 1 | up to 1/2 [12.7], excl | ± 0.005 [0.13] | ± 15 | 30 | 0 | 1/8 [3] | 0 | … |

| 2 | 1/2 to 1 1/2 [12.7 to 38.1], excl | ± 0.005 [0.13] | ± 10 | 20 | 0 | 1/8 [3] | 0 | less than 0.065 in. [1.6 mm] specified |

| 3 | 1 1/2 to 3 1/2 [38.1 to 88.9], excl | ± 0.010 [0.25] | ± 10 | 20 | 0 | 3/16 [5] | 0 | less than 0.095 in. [2.4 mm] specified |

| 4 | 3 1/2 to 5 1/2 [88.9 to 139.7], excl | ± 0.015 [0.38] | ± 10 | 20 | 0 | 3/16 [5] | 0 | less than 0.150 in. [3.8 mm] specified |

| 5 | 5 1/2 to 8 [139.7 to 203.2], incl | ± 0.030 [0.76] | ± 10 | 20 | 0 | 3/16 [5] | 0 | less than 0.150 in. [3.8 mm] specified |

FAQ

MORE DETAILS OF REALTED PRODUCTS CLICK HERE

___________________________________________________________________________________________________________________________________________

| We pay attention to every step of manufacturing, and carefully control every details from process, design, manufacture and test , in order to guarantee superexcellent product. | |

| Raw material inspection: | Dimension and tolerance check, appearance quality check ,mechanical properties testing, weight check and raw material’s quality assurance certificate check. |

| Semi-finished goods inspection: | Dimension and tolerance check ,physical and chemical Inspection ,leakage magnetism and ultrasonic inspection |

| Finished goods inspection: | Dimension and tolerance, appperance quality check and mechanical properties testing. |

| Inspection beforeex-factory: | We arrange our QC staff to manufacture’s plant for final quality and packing inspection each time before we deliver goods to port for shipping, and the connected sales staff will be with QC staff to make sure we did everything fully and strictly meet our customers’ requirements. |

Products categories

WHY CHOOSE US

Since its establishment, our factory has been developing first world class products with adhering the principle

of quality first. Our products have gained excellent reputation in the industry and valuabletrusty among new and old customers..