Welcome To MZ STEEL

Nickel Alloy C276 C22 C4 Hastelloy X Plate

| Place of Origin: | Shanghai, China |

| Type: | Nickel Plate |

| Application: | industrial |

| Grade: | Nickel |

| Ni (Min): | as standard |

| Resistance (μΩ.m): | stable |

| Powder Or Not: | Not Powder |

| Ultimate Strength (≥ MPa): | stable |

| Elongation (≥ %): | stable |

| Model Number: | Hastelloy C276 C22 C4 X |

| Brand Name: | MZ Steel |

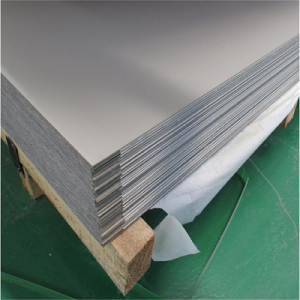

| Product name: | Nickel Alloy C276 C22 C4 Hastelloy X Plate / Sheet Price |

| Keyword: | Nickel Alloy C276 C22 C4 Sheet / Plate |

| Material: | Nickel Alloy C276 C22 C4 |

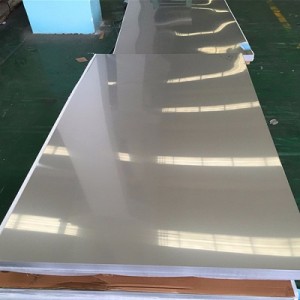

| Length: | 5.8m,6m or as your requirement |

| Width: | 1000-3000mm or customized |

| thinkness: | 0.3-300mm or customized |

| Technique: | Hot-rolled, Hot-forged, Cold-drawn, Centerless Gringing |

| Surface: | Pickling |

| Package: | Standard Seaworthy Package |

| Shape: | Round |

High temperature,corrosion resistant alloy

Grade:Inconel 625,Inconel 600,Incoloy 825,Incoloy 800,Hsatelloy C-276,etc.

Execution standard:GB/T 25827-2010,GB/T 25828-2010,GB/T 25831-2010,GB/T 25932-2010,ASTM A751,ASTM A745/388,etc.

Basic properties: high temperature corrosion resistant alloy refers to a kind of metal materials with nickel, paste or cobalt as matrix, which can withstand complex and harsh mechanical stress under high temperature environment and has good surface stability.High temperature corrosion resistant alloys generally have high room temperature and high temperature strength, good oxidation and thermal corrosion resistance, excellent creep and fatigue resistance, and good structural stability.

| Product Name | Nickel Alloy C276 C22 C4 Hastelloy X Plate / Sheet Price |

| Material | Monel/Inconel/Hastelloy/Duplex Steel/PH Steel/Nickel Alloy |

| Shape | Round,Forging,Ring,Coil,Flange,Disc,Foil,Spherical,Ribbon,Square,Bar,Pipe,Sheet |

| Grade | Duplex: 2205(UNS S31803/S32205),2507(UNS S32750),UNS S32760(Zeron 100),2304,904L |

| Others: 253Ma,254SMo,654SMo,F50(UNS S32100)F60,F61,F65,1J22,N4,N6 etc | |

| Alloy : Alloy 20/28/31; | |

| Hastelloy: Hastelloy B/ -2/B-3/C22/C-4/S/ C276/C-2000/G-35/G-30/X/N/g; | |

| Hastelloy B / UNS N10001,Hastelloy B-2 / UNS N10665 /

DIN W. Nr. 2.4617,Hastelloy C,Hastelloy C-4 / UNS N06455 / DIN W. Nr. 2.4610,Hastelloy C-22 / UNS N06022 / DIN W. Nr. 2.4602,Hastelloy C-276 / UNS N10276 / DIN W. Nr. 2.4819,Hastelloy X / UNS N06002 / DIN W. Nr. 2.4665 |

|

| Haynes: Haynes 230/556/188; | |

| Inconel Series: | |

| Inconel 600/601/602CA/617/625/713/718/738/X-750,Carpenter 20; | |

| Inconel 718 / UNS N07718 / DIN W. Nr. 2.4668,Inconel 601 / UNS N06601 / DIN W. Nr. 2.4851, Inconel 625 / UNS N06625 / DIN W. Nr. 2.4856,Inconel 725 / UNS N07725,Inconel X-750 / UNS N07750 / DIN W. Nr. 2.4669,Inconel 600 / UNS N06600 / DIN W. Nr. 2.4816 |

|

| Incoloy: Incoloy 800/800H/800HT/825/925/926; | |

| GH: GH2132,GH3030,GH3039,GH3128,GH4180,GH3044 | |

| Monel: Monel 400/K500/R405 | |

| Nitronic: Nitronic 40/50/60; | |

| Nimonic: Nimonic 75/80A/90/A263 ; | |

| Specification | Wire: 0.01-10mm Strip: 0.05*5.0-5.0*250mm Bar: φ4-50mm;Length 2000-5000mm Pipe: φ6-273mm;δ1-30mm;Length 1000-8000mm Sheet: δ 0.8-36mm;Width 650-2000mm;Length 800-4500mm |

| Product Characteristics |

1.According to the preparation process can be divided into deformation superalloys, casting superalloys and powder metallurgy superalloys. 2.According to the strengthening mode, there are solid solution strengthening type, precipitation strengthening type, oxide dispersion strengthening type and fiber strengthening type, etc.. |

| Standard | GB,AISI,ASTM,DIN,EN,SUS,UNS etc |

| Inspection | ISO,SGS,BV and so on. |

| Application | High temperature components such as turbine blades, guide vanes, turbine disks, high pressure compressor disks,machine manufacturing and combustion chambers used in the manufacture of aviation, naval and industrial gas turbines |

| Packaging | 1. cases packed in wooden cases 2. paper packaging 3. plastic packing 4. foam packaging Packaging according to customer requirements or products |

| Delivery | 7-25days or according to the product |

| Payment | L/C,D/A,D/P,T/T,Western Union,MoneyGram,According to customer requirements payments for offline orders. |

Chemical composition:

| C-276 | C(%) | Cr(%) | Ni(%) | Fe(%) | Mo(%) | W(%) | Si(%) | Mn(%) | S(%) | P(%) | V(%) | Co(%) |

| Range | ≤0.01 | 14.5-16.5 | blance | 4.0-7.0 | 15.0-17.0 | 3.0-4.5 | ≤0.08 | ≤1.0 | ≤0.04 | ≤0.03 | ≤0.35 | ≤2.5 |

Products categories

WHY CHOOSE US

Since its establishment, our factory has been developing first world class products with adhering the principle

of quality first. Our products have gained excellent reputation in the industry and valuabletrusty among new and old customers..